Flawless Visual Quality. Industrial Strength. Stravata Precision.

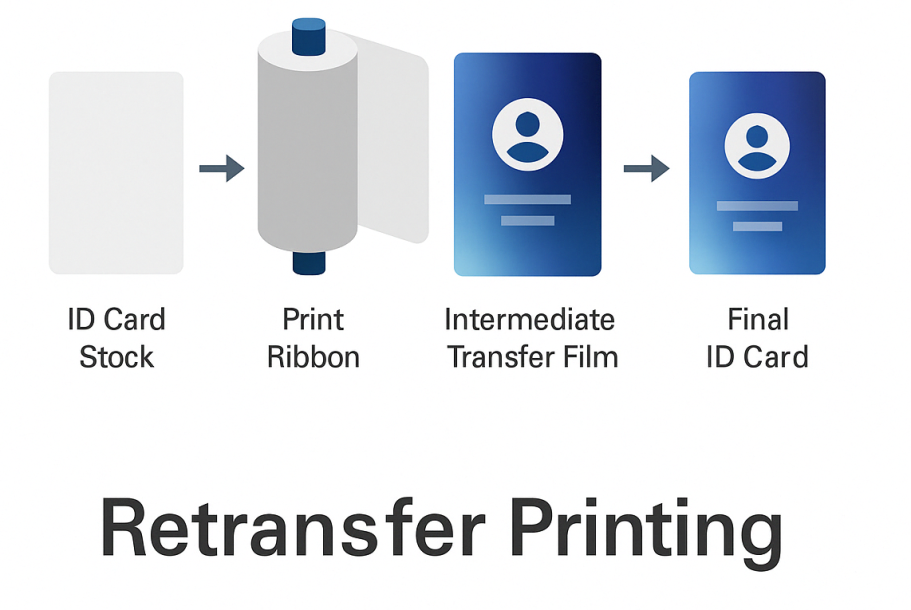

Retransfer Printing Process

Stravata Solutions uses retransfer printing to ensure every ID card we produce meets the highest standards of image quality, material flexibility, and long-term durability. Retransfer technology offers advantages that traditional direct-to-card (DTC) printing methods cannot match—especially when printing on uneven surfaces like smart cards, laminated Teslin substrates, or heavily secured cards

The Future of High-Security Card Production

Beyond Printing — Precision Engineering for Every Credential.

At Stravata Solutions, retransfer printing isn’t just a production method — it’s a commitment to excellence. By transferring your card design through a high-resolution intermediate film, rather than printing directly onto the card surface, we achieve edge-to-edge coverage, vibrant true-color imagery, and perfect alignment of critical security elements like microtext, UV features, and embedded holograms. Retransfer technology also enables printing on a wide range of substrates — from standard PVC to Teslin and complex smart cards — without sacrificing image quality or card integrity. The result is a finished credential that doesn’t just look flawless on day one, but continues to perform and protect your organization’s security standards for years to come. When quality, longevity, and precision matter, retransfer is the only choice — and Stravata delivers it with unmatched expertise.

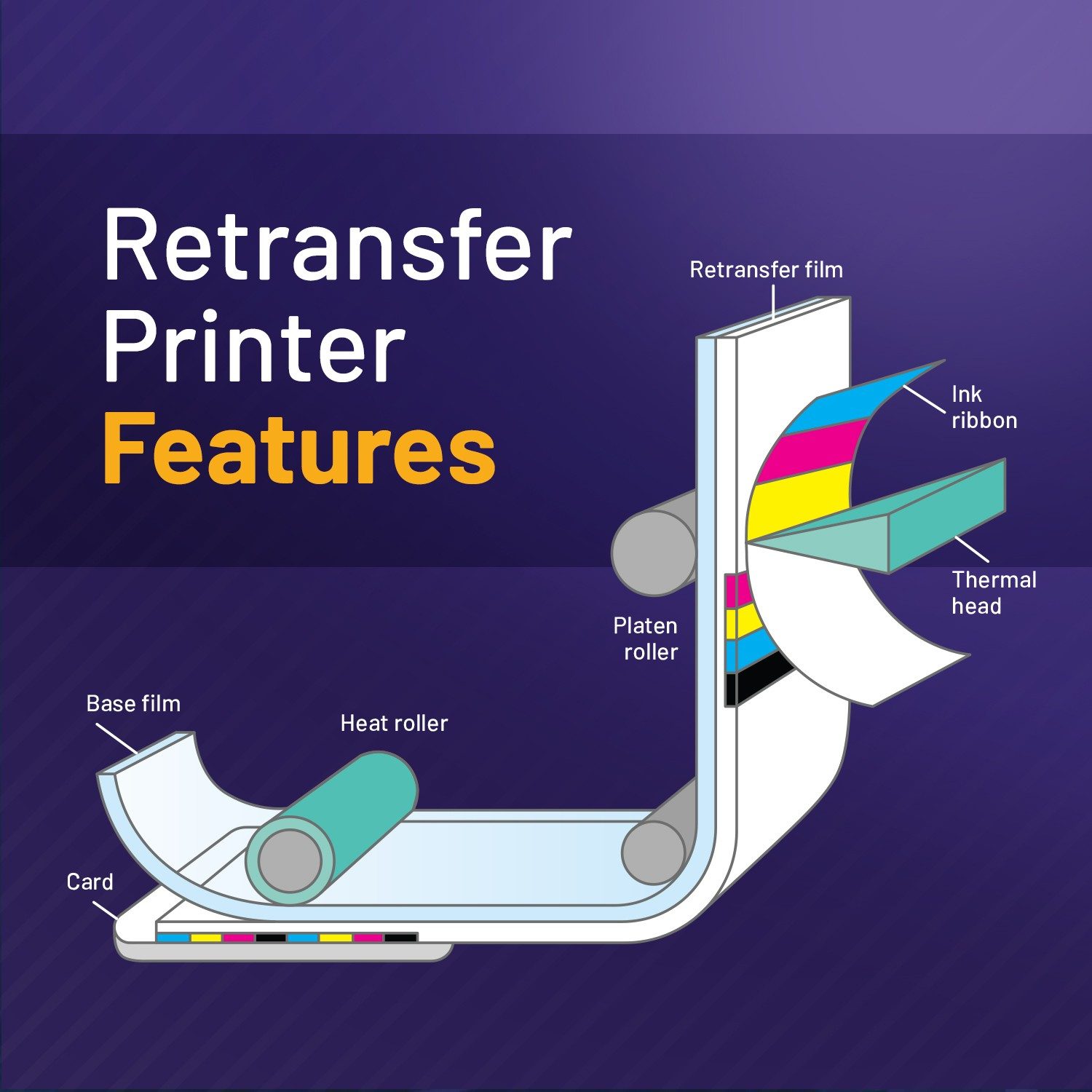

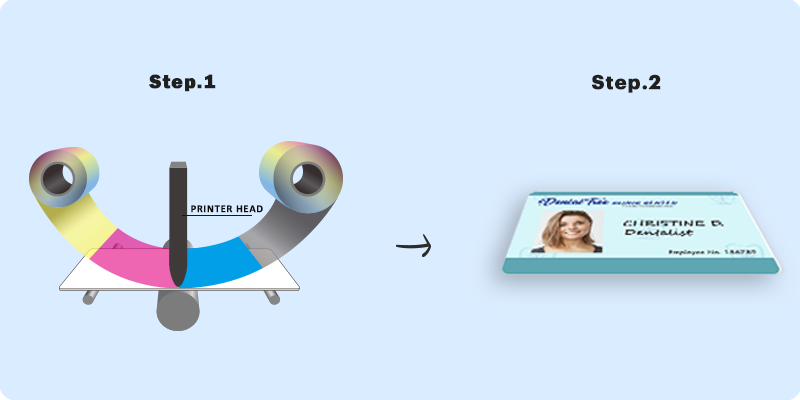

What is Retransfer Printing?

Retransfer printing is a two-step process that creates an ultra-crisp, durable image by first printing on a clear film and then thermally transferring that film onto the card surface. Unlike DTC printers, the retransfer method eliminates image distortion caused by surface inconsistencies, delivering edge-to-edge coverage and photo-realistic resolution.

How it works:

- Image is printed onto a transparent retransfer film.

- Film is then bonded to the card surface using heat and pressure.

Key Benefits:

- Consistent, high-resolution output

- No direct contact with the card surface

- Ideal for cards with embedded chips or uneven finishes

- Edge-to-edge (full-bleed) printing coverage

01

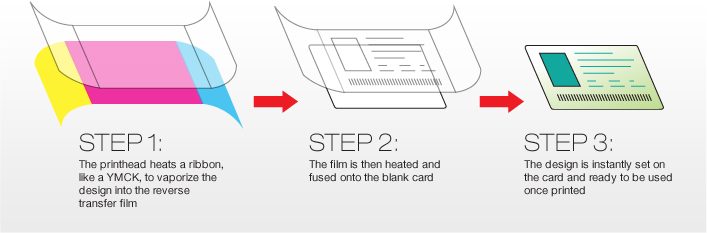

3 Key Steps

Precision Starts with the Perfect Image

Image Creation and Reverse Printing

The retransfer process begins by printing your card design onto a clear transfer film instead of directly onto the card surface. This image is printed in reverse (mirror-image) so that once transferred, it appears correctly to the viewer. By using this method, every detail — from fine text to vibrant colors — is captured at a much higher resolution than traditional direct-to-card printing. This ensures that even the most intricate security features and brand elements are reproduced with crisp, professional quality.

02

Seamless Fusion, Flawless Finish

Heat Transfer to Card Surface

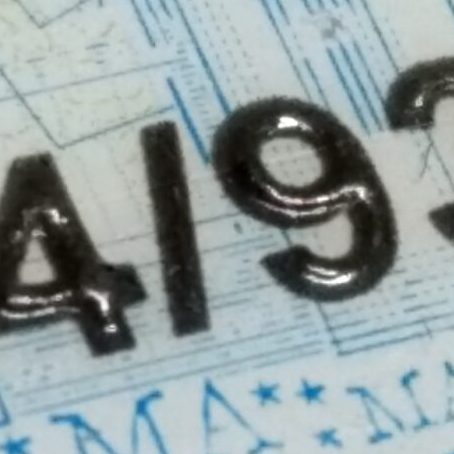

Once the image is printed onto the film, it is then fused onto the surface of the card using controlled heat and pressure. This bonding process creates a seamless, edge-to-edge coverage — even on cards with uneven surfaces like embedded chips. Unlike direct-to-card printing, retransfer printing creates a protective layer between the design and the outside world, making the finished card more resistant to scratches, UV fading, and everyday wear.

03

Ready for the Real World.

Final Protection and Enhanced Durability

After the transfer is complete, the card is now shielded by the durable film layer, locking in the image beneath it. This gives the card a glossy, professional appearance while providing exceptional protection against abrasion, moisture, and tampering. Retransfer-printed cards last significantly longer than traditional printed cards, maintainin

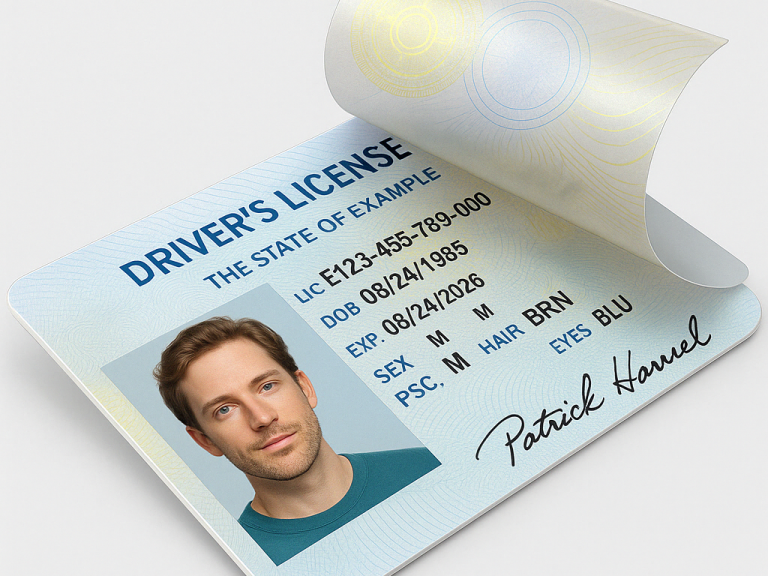

Why It Matters for Secure Credentials

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

For organizations that require security, durability, and aesthetic consistency, retransfer printing is the gold standard. Its precision enables better alignment of high-security elements—such as ghost images, microtext, and UV print zones—across the entire surface of each card.

Retransfer is also more resistant to fading, scratching, and environmental wear, making it the best option for:

Outdoor-use cards

Cards used in outdoor environments face harsh conditions such as UV exposure, moisture, temperature swings, and physical abrasion. Retransfer printing creates a protective film layer that shields the printed design, ensuring colors stay vivid, security features remain intact, and the card resists fading or peeling over time. This makes retransfer-printed cards the top choice for outdoor personnel, transportation systems, and field-based operations where durability is critical.

High-touch access cards

Access control cards are constantly handled, swiped, or tapped, making them highly susceptible to wear. Retransfer printing provides a tough, flexible surface that resists cracking, scratching, and edge wear even under heavy daily use. This extended durability ensures that visual security features like photos and printed data remain clear and legible, while also prolonging the life of proximity chips and magnetic stripe systems embedded within the cards.

Ideal for:

- Smart cards and access cards

- Teslin laminated credentials

- ID cards with over-the-edge design layouts

Long-lifespan government or institutional credentials

Government and institutional ID cards often need to maintain functionality and appearance for several years without replacement. Retransfer printing produces photo IDs and credentials with exceptional visual quality, edge-to-edge protection, and strong resistance to counterfeiting techniques. Whether for driver’s licenses, national ID cards, or university IDs, retransfer technology supports high-end security printing like microtext, ghost images, and UV overlays, helping institutions maintain operational security and identity integrity.

Mission-critical employee or contractor ID badges

For industries where security breaches or credential failures could have serious consequences, employee and contractor badges must be extremely durable and tamper-resistant. Retransfer printing ensures these high-security credentials can withstand challenging environments such as construction sites, manufacturing plants, laboratories, and secure access areas. By delivering maximum image protection and structural strength, retransfer-printed badges help organizations maintain compliance, safety, and operational reliability every day.

Materials We Use

Stravata leverages a variety of compatible card materials to suit your specific application

Print Specs & Customization Options

With retransfer, Stravata is able to deliver:

600 to 1200 DPI printing resolution

CMYK full-color printing with optional UV fluorescent overlays

Edge-to-edge graphics with high alignment accuracy

Integrated print zones for microtext, ghost photos, and tactile layers

Compatibility with magnetic stripe and chip encoding

Our retransfer system is optimized to handle these substrates while maintaining color accuracy, sharpness, and professional finish. The materials Retransfer Printing is capable on are:

Teslin Substrate: Durable, secure, and perfect for laminated applications

PVC & PVC Composite: Standard for most ID cards

PET & PET-G: Heat-resistant and durable, ideal for extended use environment

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nulla euismod condimentum felis vitae efficitur. Sed vel dictum quam, at blandit leo.

Customization Add-Ons:

Tactile raised printing

Lamination pouches with embedded threads

Multi-format barcodes and QR/NFC zones

Teslin PVC Composite Cards (Teslin + PVC overlay)

Teslin core (a synthetic paper) sandwiched between thin PVC plastic laminate layers.

Slightly flexible, but stronger and more impact-resistant than regular PVC.

Matte or slightly textured surface if uncoated, but usually glossy when laminated.

Softer “bend feel” than pure plastic cards.

Pure PVC Cards (100% Polyvinyl Chloride)

Completely plastic, smooth, and very glossy.

Firm but slightly flexible depending on thickness (30 mil is standard).

Feels solid and slick in the hand, similar to a credit card.

PETG Cards (Polyethylene Terephthalate Glycol-modified)

A plastic card with a smooth, glossy surface but slightly “softer” than PVC.

Slightly more flexible and less brittle than PVC.

Surface feels sturdy but can have a very faint “rubbery” texture compared to pure PVC.

PET Cards (Pure Polyethylene Terephthalate)

Thin, smooth, and very firm plastic — much stiffer than PETG or PVC.

Slightly more transparent if not layered or printed; otherwise very solid.

Hard, almost “crisp” feeling when flexed — less flexibility overall.

Tagline

Get To Know Our Materials

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nulla euismod condimentum felis vitae efficitur. Sed vel dictum quam, at blandit leo.

Enhanced Clarity and strength With a Sustainable Edge.

PETG Cards

Stronger environmental resistance (less cracking from cold, heat, UV).

Greener option — recyclable and lower emissions in production.

Prints well with retransfer printers; some slight challenges for direct-to-card (DTC) printers if surface is not perfectly smooth.

Tough, Eco-Conscious Performance For Demanding Enviroments.

PET Cards

Extremely high durability, even higher than PETG and PVC.

Excellent for long-life secure credentials (e.g., government IDs).

More expensive and harder to print directly (retransfer printers strongly recommended).

Classic Durability for Everyday Identification.

Pure PVC Cards

Inexpensive, easy to print on (especially with direct-to-card printers).

Good for basic ID cards, membership cards, gift cards.

More prone to cracking or bending over time under heavy use or exposure to sunlight/heat.

Flexible Strength For High-Security Credentials.

Teslin PVC Composite Cards

Very durable and resistant to cracking.

Excellent for laser engraving, retransfer printing, and embedded security features.

Absorbs ink and adhesives extremely well due to Teslin’s microporous structure.

Ready to Print with Precision?

Stravata Solutions offers premium retransfer printing to elevate your ID programs. Reach out to learn how we can deliver industrial-quality identity cards tailored to your needs.

A Difference You Can See

Retransfer printing isn’t just about looking good—it’s about lasting longer and performing better under real-world conditions. Whether your cards are swiped 20 times a day, exposed to weather, or embedded with advanced smart tech, retransfer helps them go the distance.

Stravata’s Promise

Crisper images

Stronger cards

Better security

Every time.

©Copyright. All rights reserved. 2025

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.